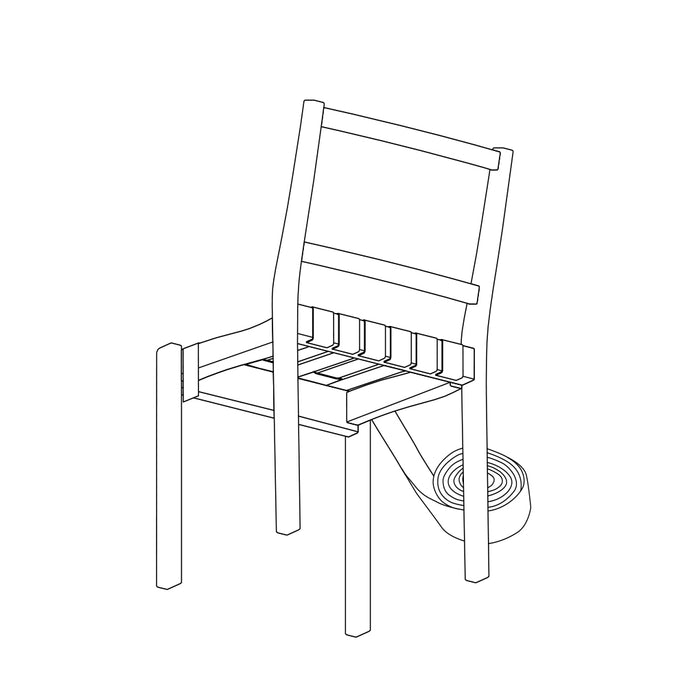

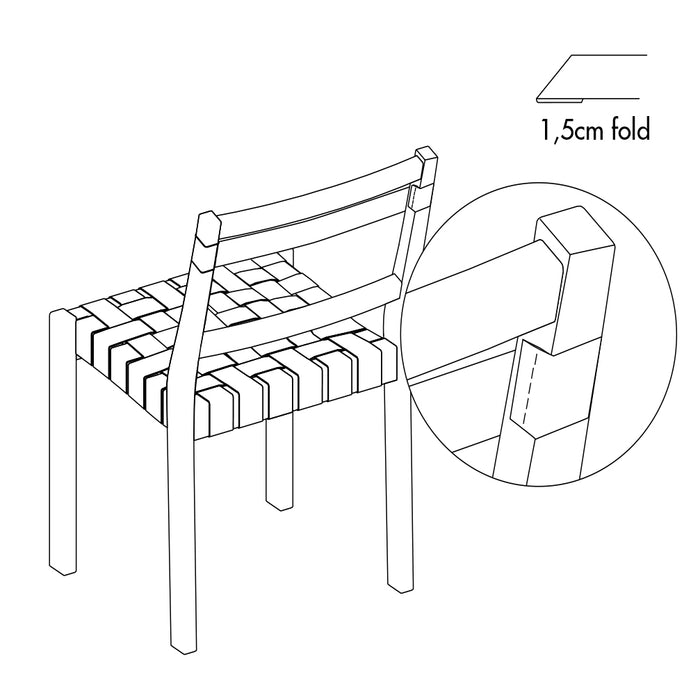

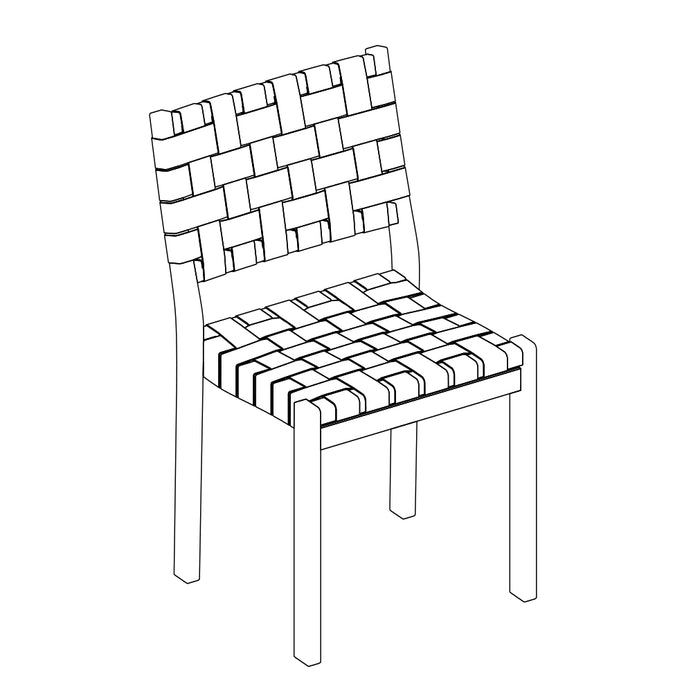

Early on in his career Alvar Aalto adopted webbing belts as alternative to classic upholstery. Ever since, webbing - a natural material made of 100% linen with a low consumption of resources - has been an elegant way to cover furniture with a slim silhouette.

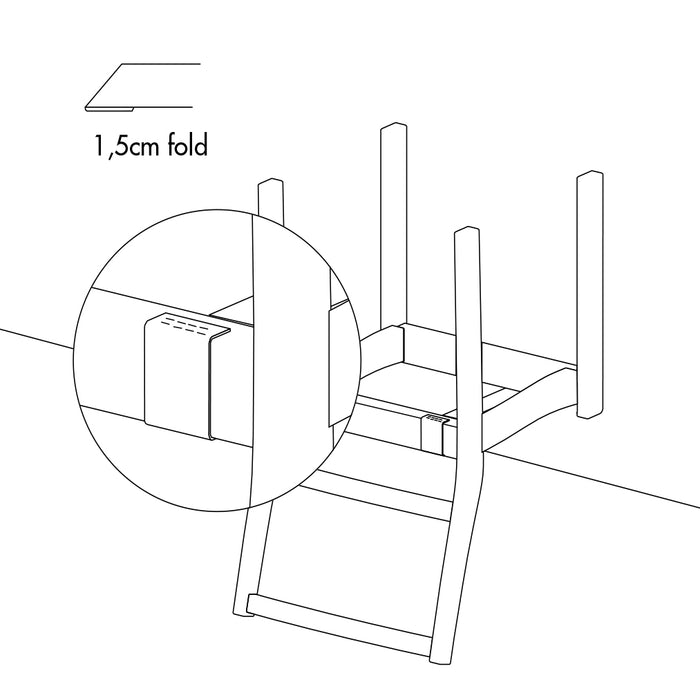

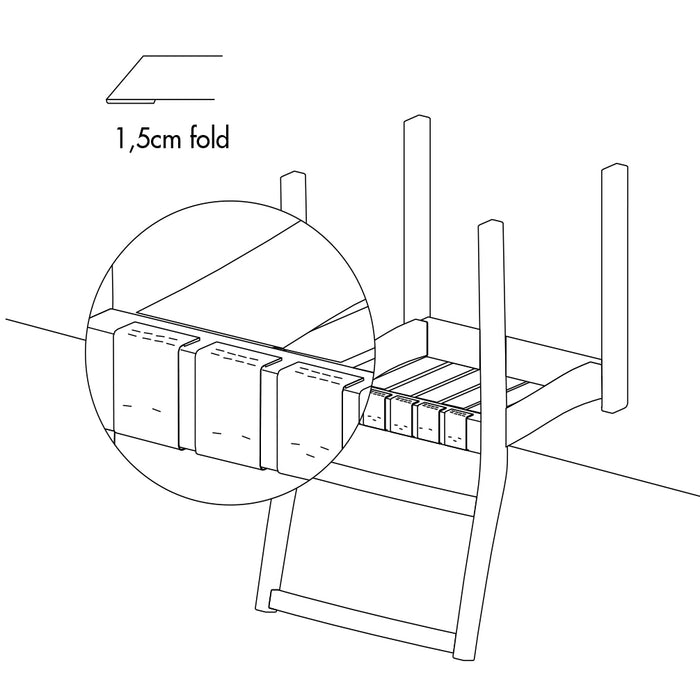

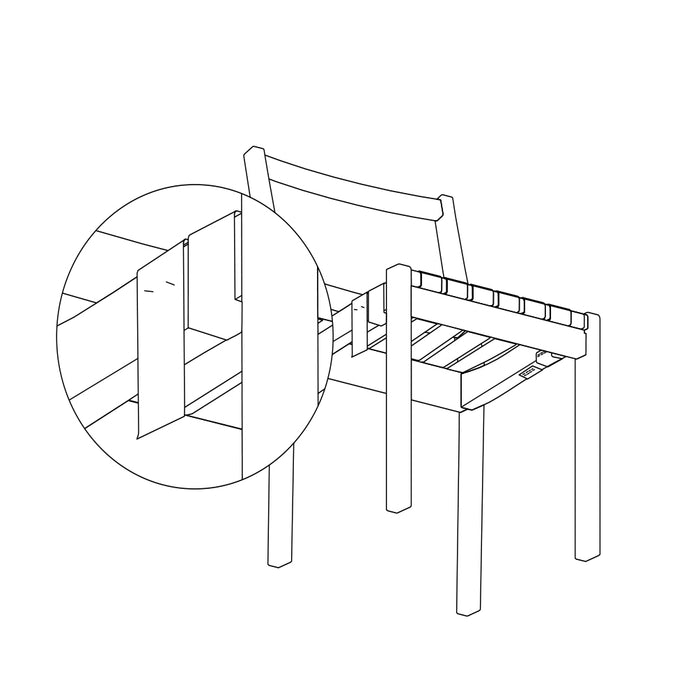

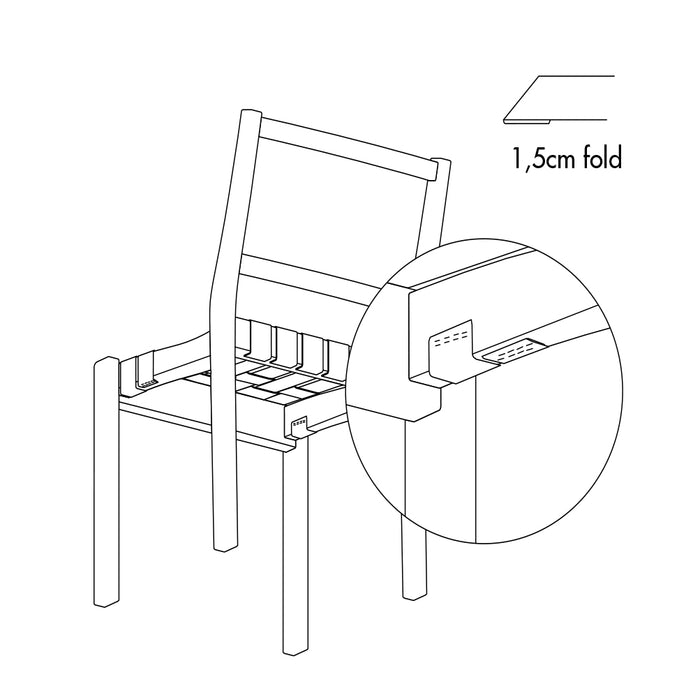

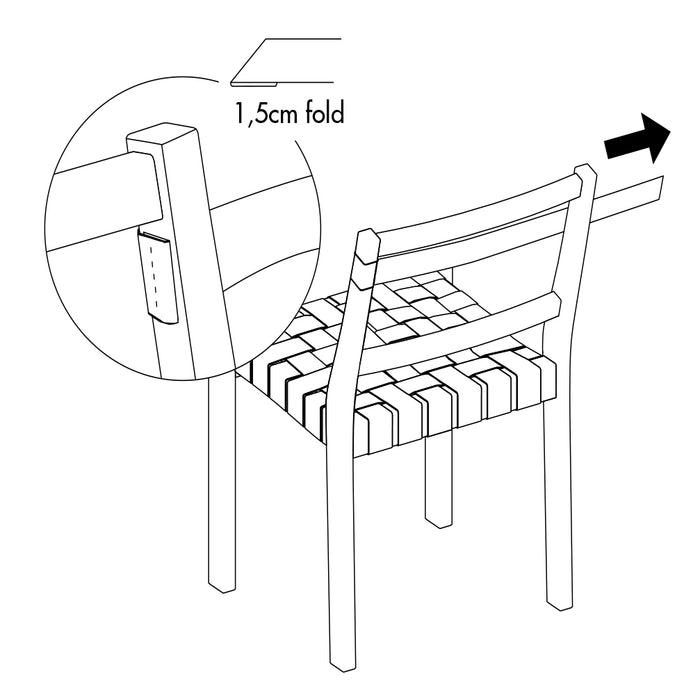

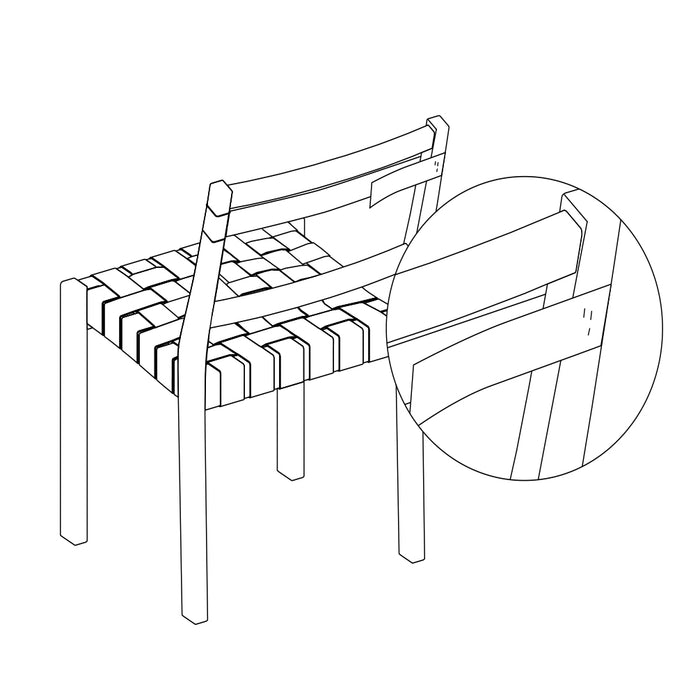

After several years of use, the webbing may lose its tension upon which it needs to be replaced. Since Artek’s furniture is designed with longevity in mind, the webbing can easily be renewed, ensuring that the product goes through several life cycles.

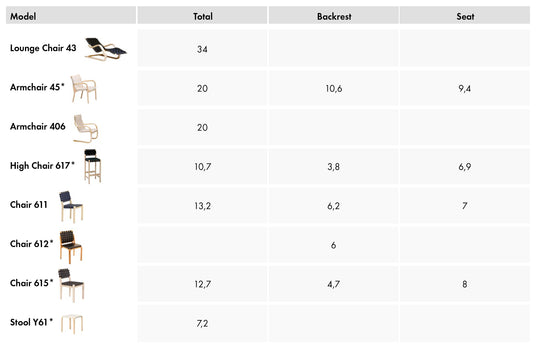

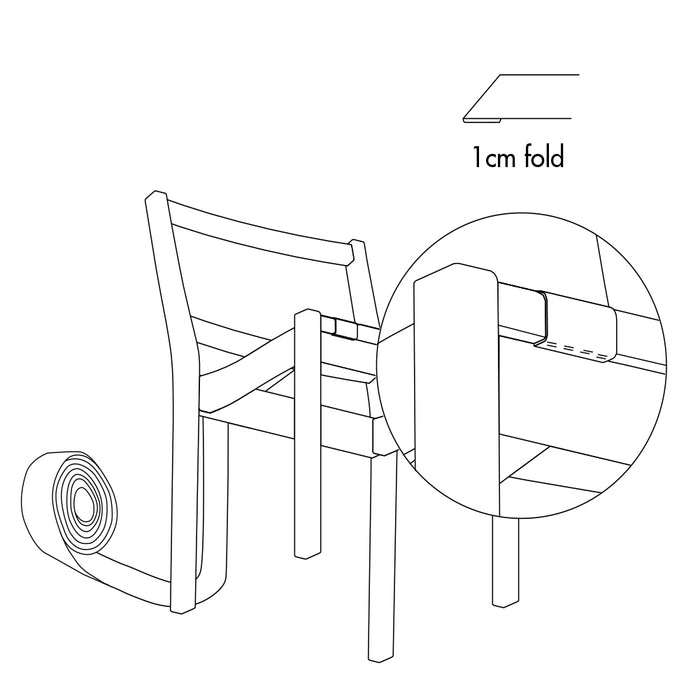

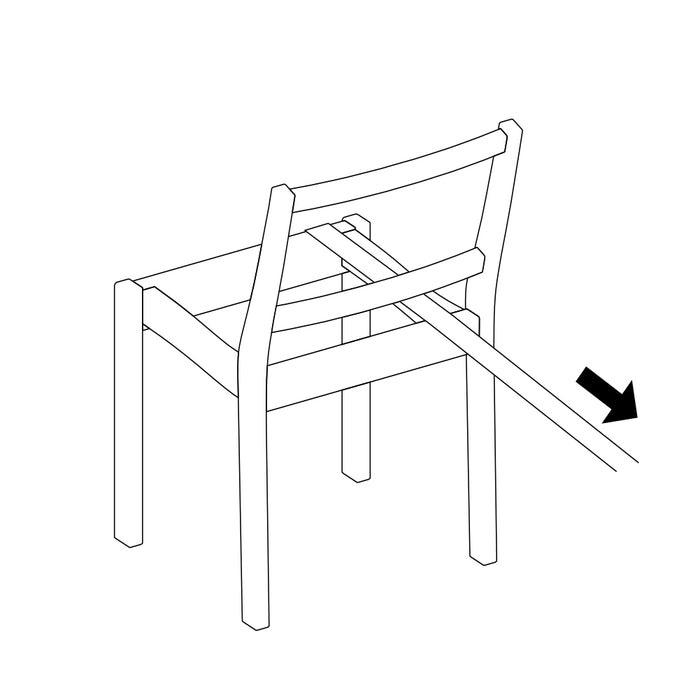

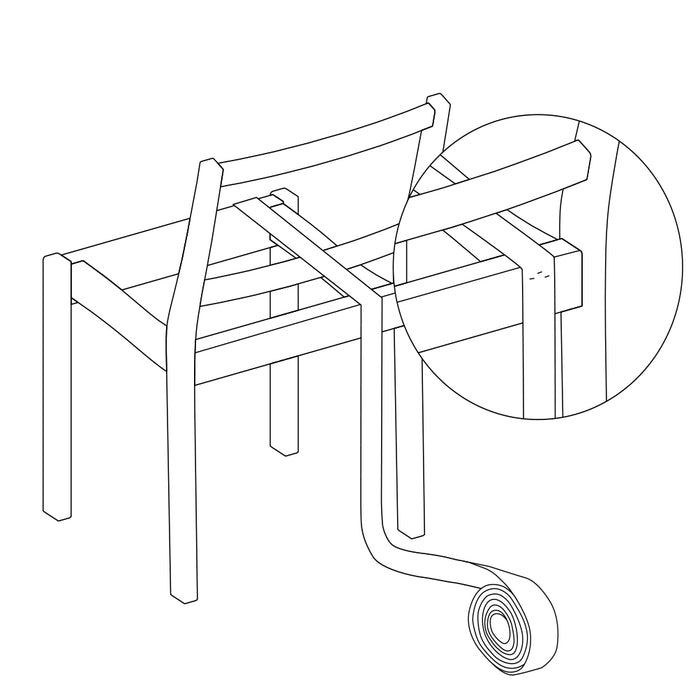

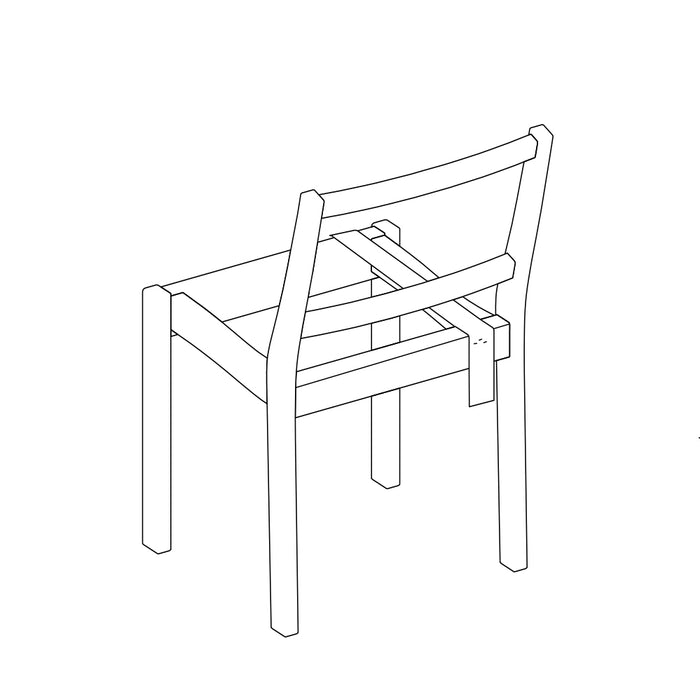

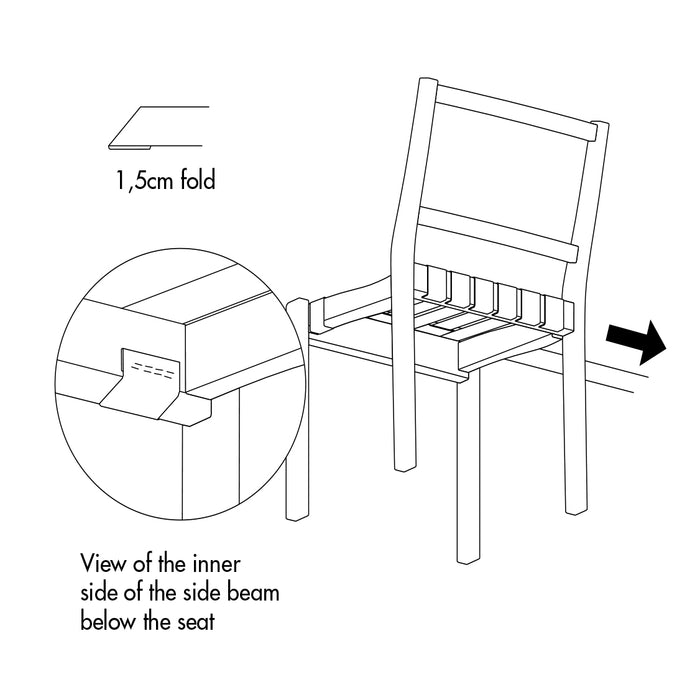

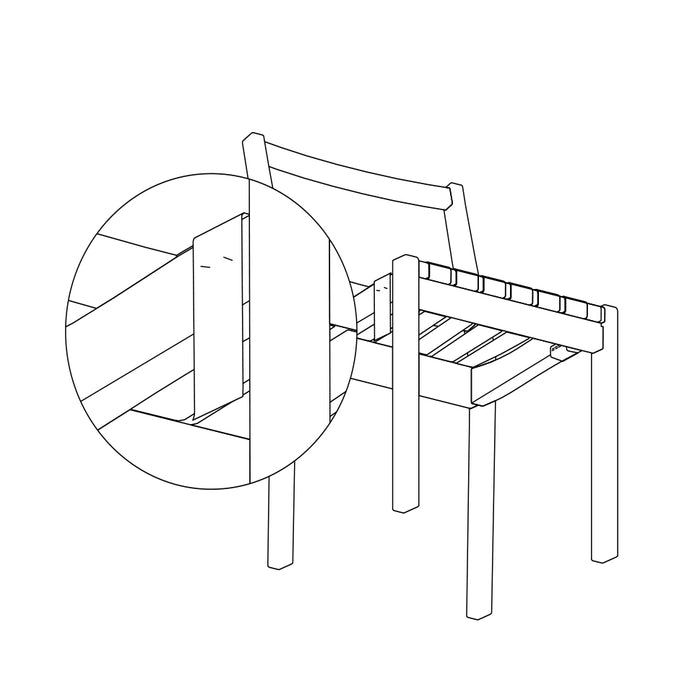

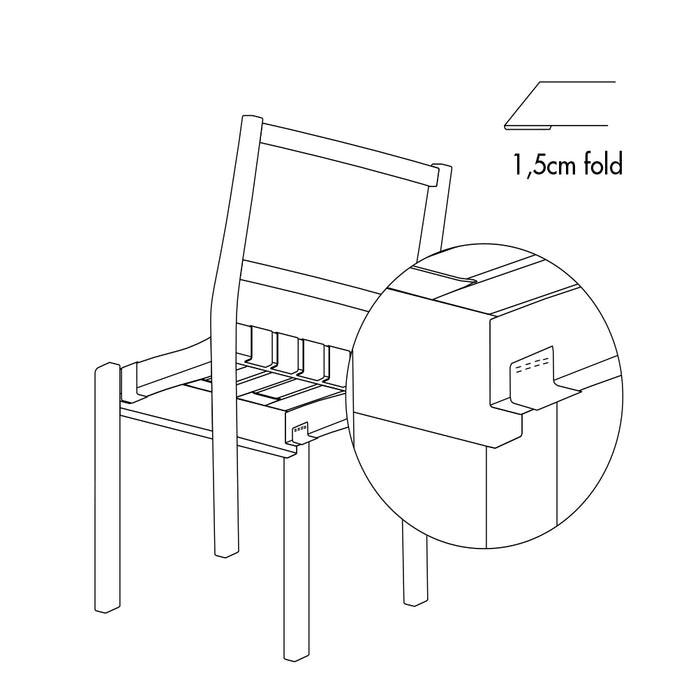

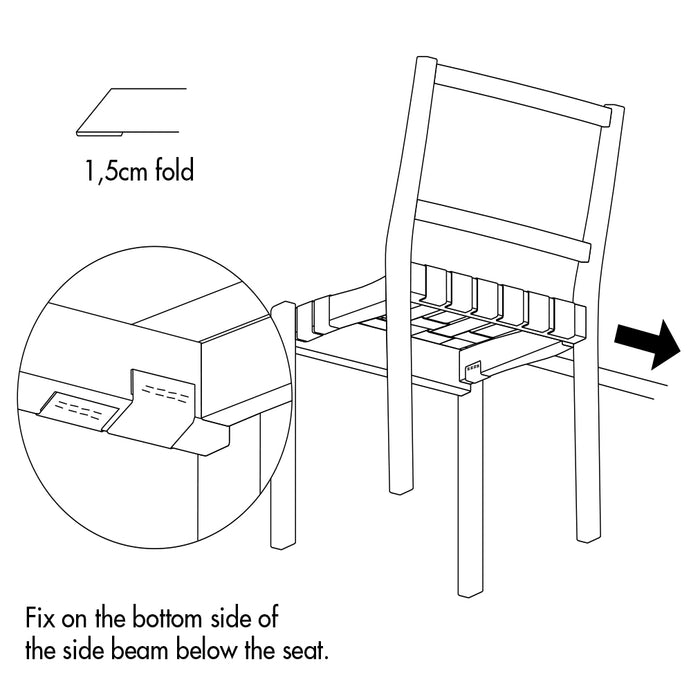

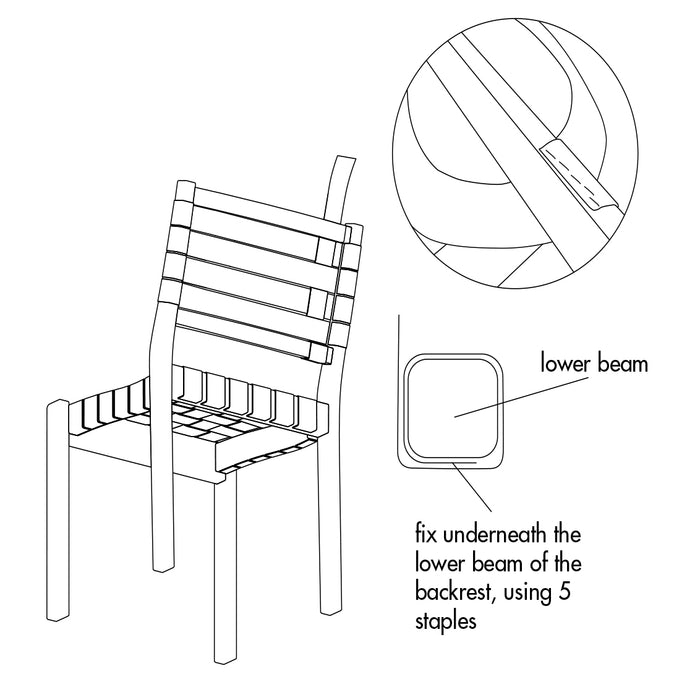

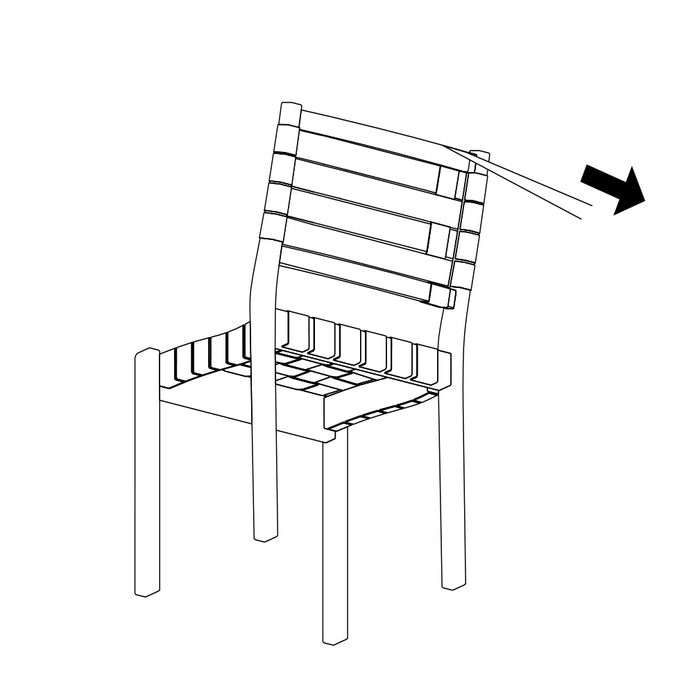

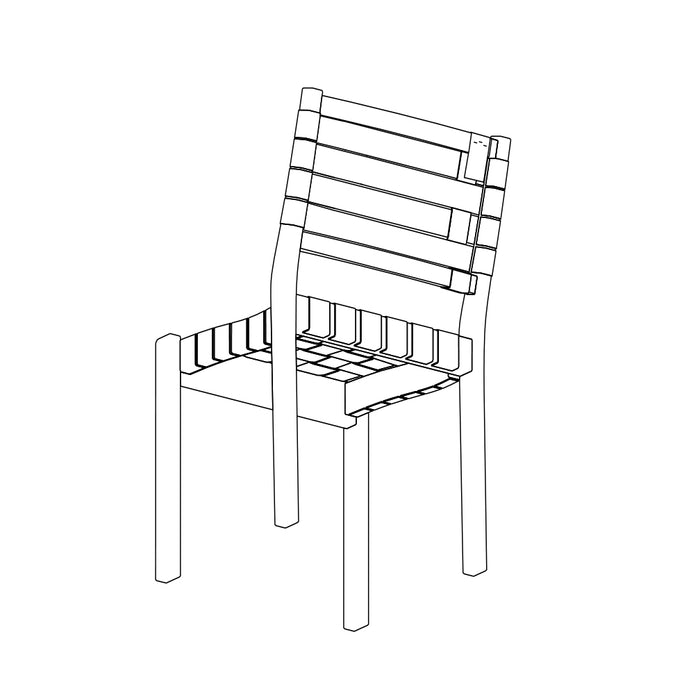

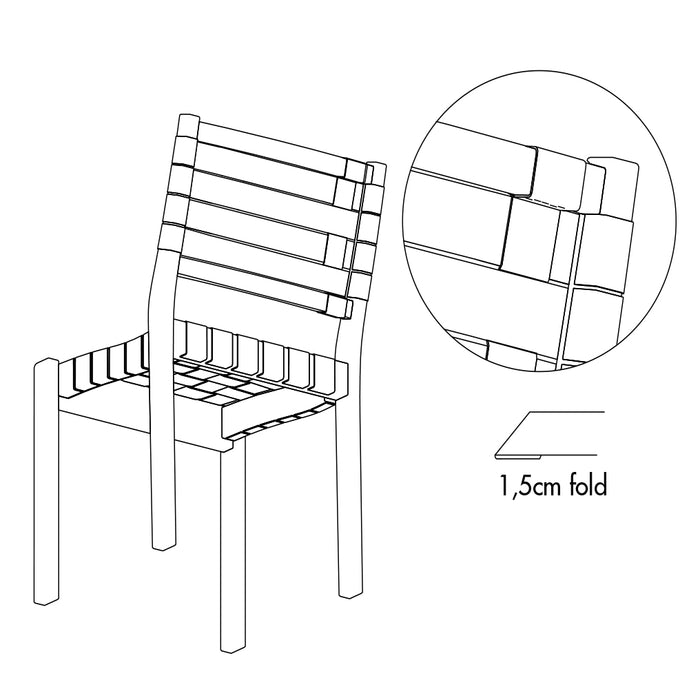

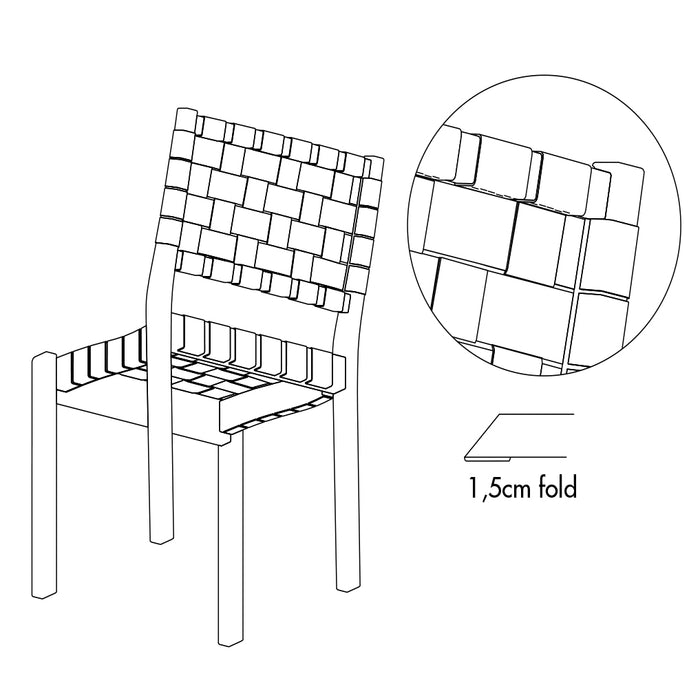

This guide lists all specifications needed for re-webbing, as well as a step-by-step instruction for professional upholsterers to re-web Alvar Aalto’s Chair 611.